Reddy Update: Difference between revisions

From IntRoLab

| Line 151: | Line 151: | ||

== Motor Controller Variables == | == Motor Controller Variables == | ||

<pre> | |||

typedef struct _SharedVariables | |||

{ | |||

union { | |||

struct { | |||

unsigned char CtrlMode; | |||

unsigned char CtrlType; | |||

unsigned char SetPointSource; | |||

unsigned char PosMesSource; | |||

unsigned short ErrorCode; | |||

short SetPoint; | |||

short SetPointMax; //Maximum SetPoint | |||

short SetPointMin; //Minimum SetPoint | |||

short Current; | |||

short CurrentOffset; | |||

short ADCValue; | |||

short ADCOffset; | |||

short ICValue; | |||

short ICOffset; | |||

short ThermalState; | |||

//CONTROL VARIABLES | |||

short Speed;//16 bit speed | |||

short Position; //16 bits position | |||

short Acceleration; | |||

//PID REF AND MES POINT | |||

short RefPoint; | |||

short MesPoint; | |||

float pid_kp; | |||

float pid_ki; | |||

float pid_kd; | |||

float pid_error; | |||

float pid_error_accum; | |||

float pid_error_derivative; | |||

float pid_error_accum_max; //PID I value max limit (abs) | |||

short PIDOut; | |||

//RAM LOC7 (PID + TRAPZ VARIABLES) | |||

short SpeedMax; //for Trapz | |||

short AccelerationStep; //for Trapz, Speed | |||

//RAM LOC8 (TRAPZ VARIABLES) | |||

short InitPoint; //for Trapz | |||

short DestPoint; //for Trapz | |||

short NextPoint; //for Trapz | |||

//RAM LOC9 (CURRENT LIMIT) | |||

short CurrentLimit; //unit = mA | |||

short PWM_CurrentLimit; | |||

short PWM_CurrentStep; //PWM increment | |||

unsigned char CurrentLimitActive; | |||

unsigned char EncoderBias; //Setting this to 1 will invert the encoder sign | |||

unsigned char MotorBias; //Setting this to 1 will invert motor polarity | |||

unsigned char padding[3]; | |||

} __attribute__((packed)); | |||

unsigned char m_data[]; | |||

}; | |||

} SharedVariables; | |||

typedef struct _GlobalVariables | |||

{ | |||

union { | |||

struct { | |||

//All control variables | |||

SharedVariables m_variables[4]; | |||

//additional (global) variables | |||

unsigned char m_ESTOPEnabled; | |||

unsigned char m_WriteEEPROM; | |||

short m_loopTime; | |||

unsigned char m_padding[4]; | |||

} __attribute__((packed)); | |||

unsigned char m_data[]; | |||

};//union | |||

} GlobalVariables; | |||

</pre> | |||

== Useful Examples == | == Useful Examples == | ||

Revision as of 15:06, 28 July 2009

Schedule

| Week 31, July 27 - August 1 |

|

| Week 32, August 3 - August 9 |

|

| Week 33, August 10 - August 15 |

|

Arm Improvements

To have better control of the arm (and neck) motors, we did the following :

- Change the Motor PCB to support

- Temperature detector. A signal will be sent to the motor controller if the motor temperature is higher than 60 degrees celcius. Analog temperature value is also available.

- Potentiometer feedback.

- Motor power connection.

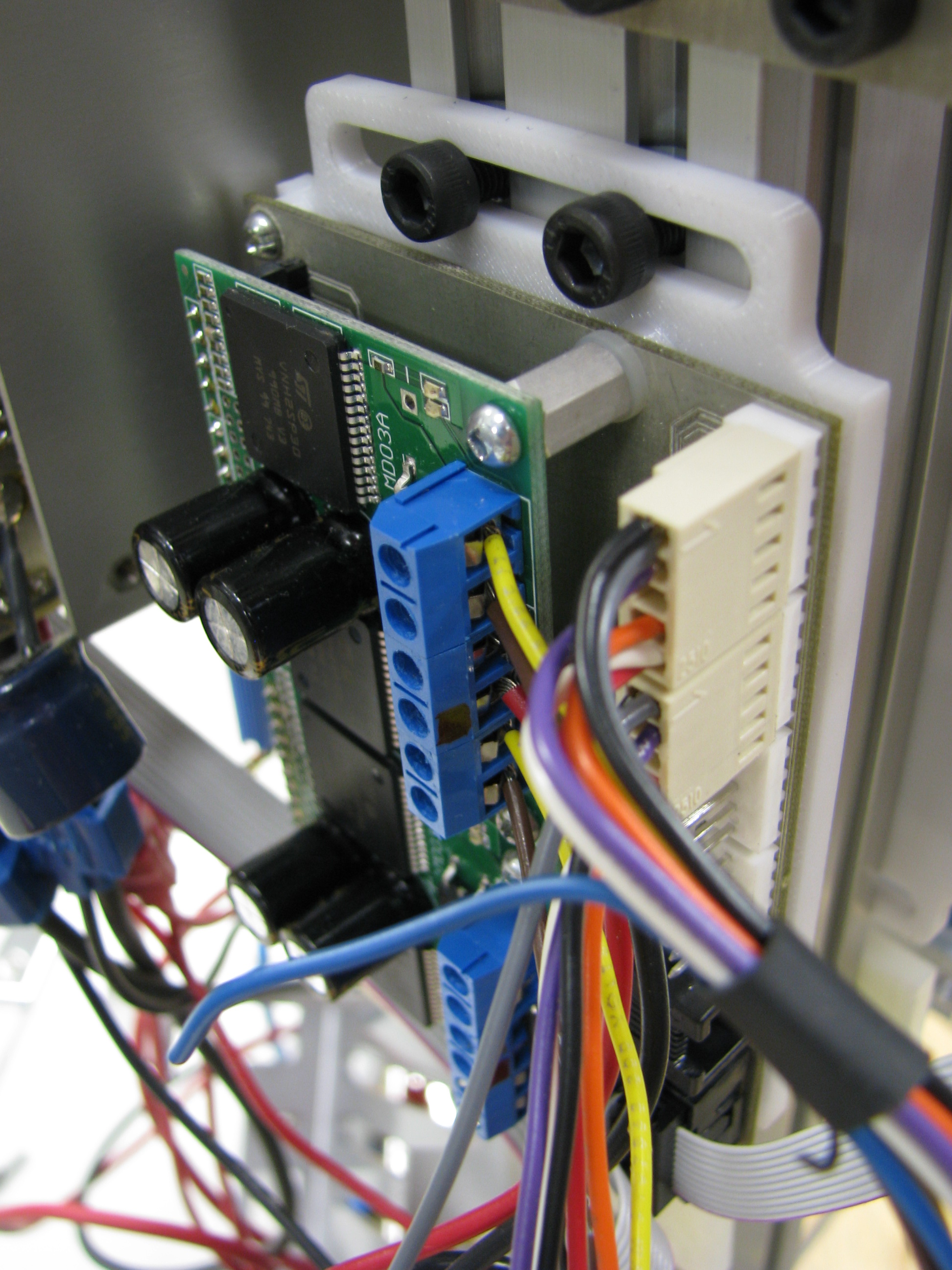

- Design a new PCB with support to 4 motors

- Communicate with the CAN bus already available on Reddy

- Allow position feedback from the RS-232 interface

- Create a tuning GUI for easier setup of the robot controllers

Motor PCB

Motor Controllers

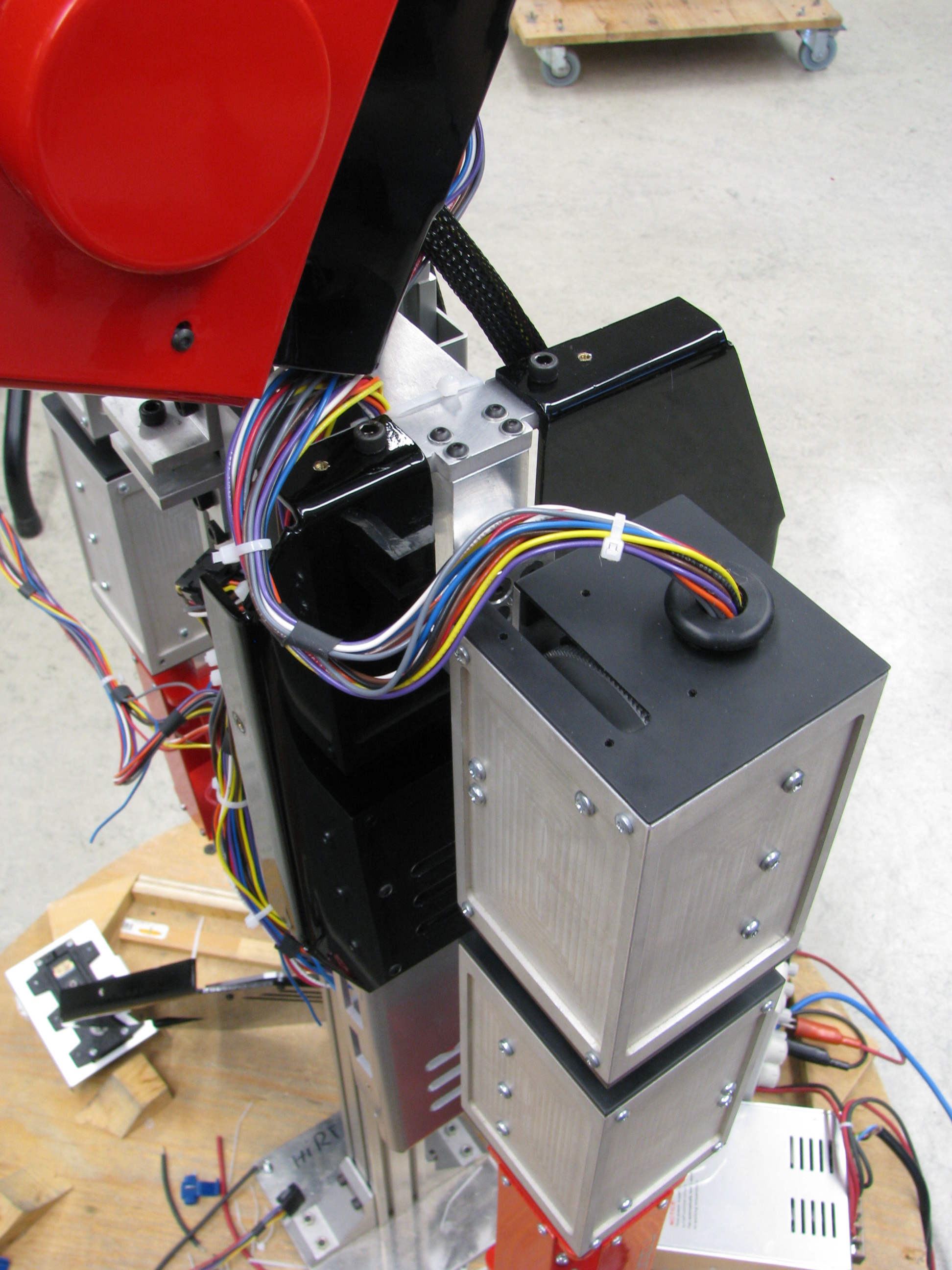

- A new motor drive that can connect up to 4 motors have been designed.

- A new adjustable bracket for fixing the drive to the side of the robot have been designed.

- We installed two motor controllers (one on each side) to allow the modification of 8 motors. Motors modified are :

- Arm-elbow (x2)

- Arm-shoulder (x2)

- Arm-updown (x2)

- Neck-YES (x1)

- Neck-NO (x1)

Cabling Improvements

- Cables are now better organized

- Added connectors inside the arm to disconnect motors easily for repairs

- Signals are color coded as follow (TODO ADD DOCUMENTATION)

- Red

- Green

- Black

- Yellow

- Purple

- Gray

- White

- Blue

Head Improvements

File:ReddyGravityCompensation.jpg

Motor controllers for head movement (YES-NO)

- Same motor controllers were used for the neck to add overheating protection and better feedback / control

- Internal servo potentiometers were used for position control.

Tuning the motor controller

A GUI was created to facilitate motor tuning.

RS-232 protocol enhancements

- We added a CAN command to the RS-232 robot interface to allow direct communication with the motor controllers. The RS-232 robot interface now acts as a RS-232 to CAN bridge and bidirectional communication is now possible. This will allow feedback from the motor controllers (current, position, speed, etc.)

(RS-232 CAN COMMAND) <------------------------> (MOTOR DRIVE CAN INTERFACE)

CAN command format for RS-232 communication

Serial messages containing CAN commands will have the following stucture :

| HEADER | CAN_MSG_PRI_MSB_CMD | CAN_MSG_TYPE | CAN_MSG_BOOT_RTR_LENGTH | CAN_MSG_CMD | CAN_MSG_DEST | CAN_MSG_DATA |

| (3 bytes) | (1 byte) | (1 byte) | (1 byte) | (1 byte) | (1 byte) | (8 bytes) |

|

|

|

|

if (MSG_TYPE == REQUEST)

endif if (MSG_TYPE == SENSOR_HIGH_PRIORITY)

endif |

|

|

Note: It is not essential to understand the structure of the CAN messages. Souce code will be provided to format the data correctly.

Motor Controller Variables

typedef struct _SharedVariables

{

union {

struct {

unsigned char CtrlMode;

unsigned char CtrlType;

unsigned char SetPointSource;

unsigned char PosMesSource;

unsigned short ErrorCode;

short SetPoint;

short SetPointMax; //Maximum SetPoint

short SetPointMin; //Minimum SetPoint

short Current;

short CurrentOffset;

short ADCValue;

short ADCOffset;

short ICValue;

short ICOffset;

short ThermalState;

//CONTROL VARIABLES

short Speed;//16 bit speed

short Position; //16 bits position

short Acceleration;

//PID REF AND MES POINT

short RefPoint;

short MesPoint;

float pid_kp;

float pid_ki;

float pid_kd;

float pid_error;

float pid_error_accum;

float pid_error_derivative;

float pid_error_accum_max; //PID I value max limit (abs)

short PIDOut;

//RAM LOC7 (PID + TRAPZ VARIABLES)

short SpeedMax; //for Trapz

short AccelerationStep; //for Trapz, Speed

//RAM LOC8 (TRAPZ VARIABLES)

short InitPoint; //for Trapz

short DestPoint; //for Trapz

short NextPoint; //for Trapz

//RAM LOC9 (CURRENT LIMIT)

short CurrentLimit; //unit = mA

short PWM_CurrentLimit;

short PWM_CurrentStep; //PWM increment

unsigned char CurrentLimitActive;

unsigned char EncoderBias; //Setting this to 1 will invert the encoder sign

unsigned char MotorBias; //Setting this to 1 will invert motor polarity

unsigned char padding[3];

} __attribute__((packed));

unsigned char m_data[];

};

} SharedVariables;

typedef struct _GlobalVariables

{

union {

struct {

//All control variables

SharedVariables m_variables[4];

//additional (global) variables

unsigned char m_ESTOPEnabled;

unsigned char m_WriteEEPROM;

short m_loopTime;

unsigned char m_padding[4];

} __attribute__((packed));

unsigned char m_data[];

};//union

} GlobalVariables;

Useful Examples

Read all motor positions from the motor controller

Write the SetPoint of motor [0-3]

Future Improvements

- Single 12V power supply could be useful for direct connection to Pioneer robots. A 12V-->8.5V DC-DC (100W) converter is required for this operation. This item can be ordered at Vicor. 8.5V batteries would then be useless.